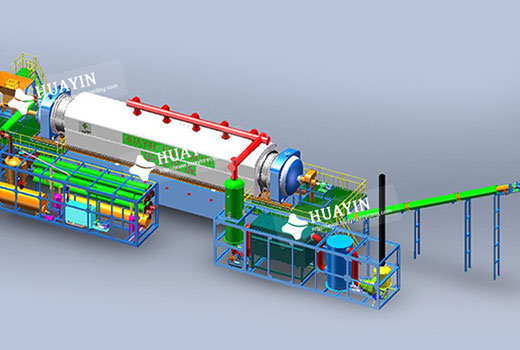

Continuous Pyrolysis Plant

| Technical data | HY-30 Continuous thermal decomposition plants |

| Capacity | 5-30 tons/day |

| Voltage | 380V/50hz |

| Electric power consumption | 11KW |

| Alternative fuel type for startup | Natural gas/heavy fuel oil |

| Heavy fuel oil | 800kg/Day |

| Lead time | 45Days |

| Plant minimum area occupied | 32 meters length, 15 meters width, 10 meters height |

| Condensation assembly weight | 7±5% tons |

| Pyrolysis reactor weight | 40±5% tons |

| Pyrolysis reactor diameter | 1700 mm |

| Maximum temperature of oil gas | 200 ℃ |

| Cooling media type and its temperature at the inlet of the HX | Cooling water no more than 40 ℃ |

| Required utilities | Initial cooling water supply Electric power supply |

|

Technical data |

HY-30 Continuous thermal decomposition plants |

|

Capacity |

5-30 tons/day |

|

Voltage |

380V/50hz |

|

Electric power consumption |

11KW |

|

Alternative fuel type for startup |

Natural gas/heavy fuel oil |

|

Heavy fuel oil |

800kg/Day |

|

Lead time |

45Days |

|

Plant minimum area occupied |

32 meters length, 15 meters width, 10 meters height |

|

Condensation assembly weight |

7±5% tons |

|

Pyrolysis reactor weight |

40±5% tons |

|

Pyrolysis reactor diameter |

1700 mm |

|

Maximum temperature of oil gas |

200 ℃ |

|

Cooling media type and its temperature at the inlet of the HX |

Cooling water no more than 40 ℃ |

|

Required utilities |

Initial cooling water supply Electric power supply |

1. Solid wastes (plastic/tyre/rubber) is fed by screw conveyor from the hopper.

2. The pyrolysis reactor is heated by the fuel burner. When the heat temperature rises to the set value, the decomposition process starts.

3. After the operation process is stable, heating is carried out by gas burner operating on pyrolysis gas.

4. From the pyrolysis reactor, the oil gas goes into condensers. Then it is cooled in the heat exchanger.

5. Oil gas enters the condenser, cools down to liquid while the non-condensed gas is used as fuel to sustain the heating process, enhancing its performance and significantly reducing operating cost.

6. The solid residue is discharged from the lower part of the reactor and shifted to receiving hoppers by the screw conveyor without oxygen access.

Thermal decomposition plant is equipped with online monitoring modules, requiring internet access for data recording.

English

English Pусский

Pусский

.jpg)